Senior Capstone Design Project

September 2017 – March 2018

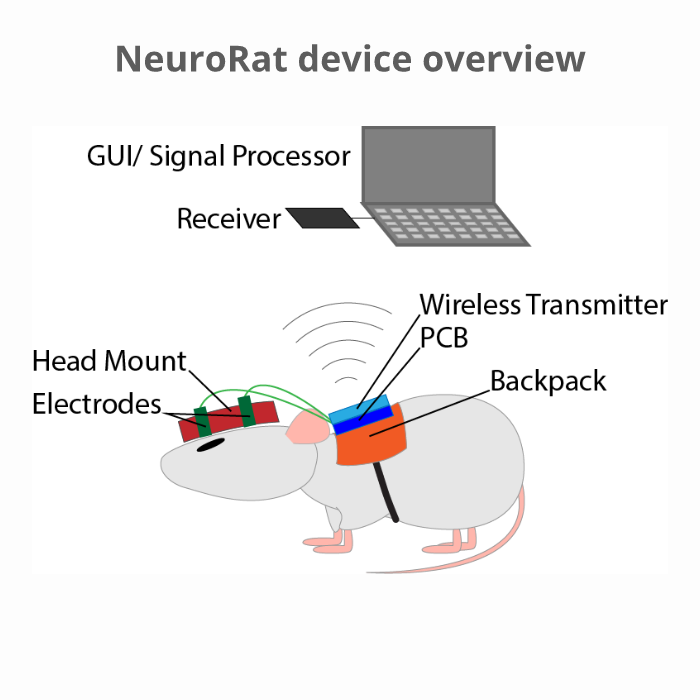

NeuroRat: A Non-invasive and Wireless Electroencephalogram for Juvenile Sprague Dawley Rats

UCLA Department of Bioengineering

Skill Highlights

Overview

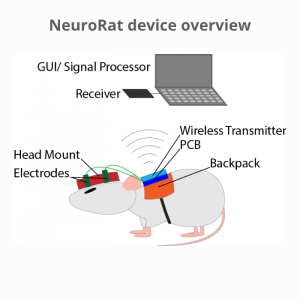

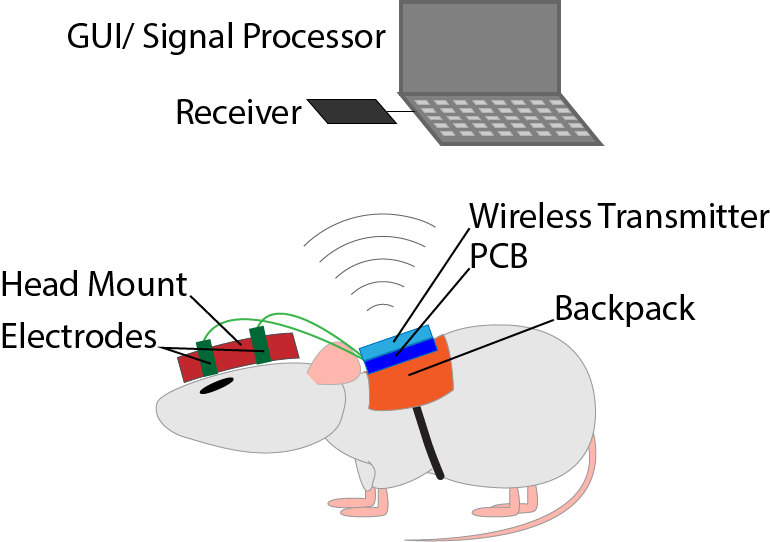

Pediatric brain injury affects 1 million children each year. Researchers study how these injuries affect brain development, and possible treatments to undo damage to the brain. To study brain injury, researchers use electroencephalograms (EEG) to record electrical activity in the brain. Currently, EEG devices are invasive and expensive, since the electrodes must be inserted into the rat’s skull surgically. To address with issue, our team created NeuroRat, a non-invasive, scalp EEG device for use on small animals.

The project had two main obstacles to overcome: how do we securely attach electrodes to the rat’s scalp in a specific location, with minimal movement and maximum accuracy? How do we implement circuitry to capture the EEG signals without weighing down the rats or limiting their mobility?

My Contributions

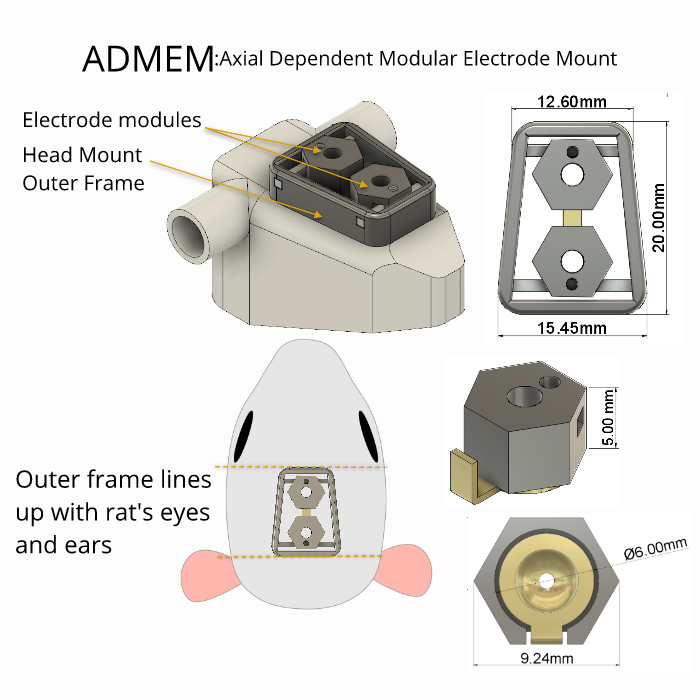

I tackled the first design challenge: designing the electrode mounts to attach to the rat’s scalp.

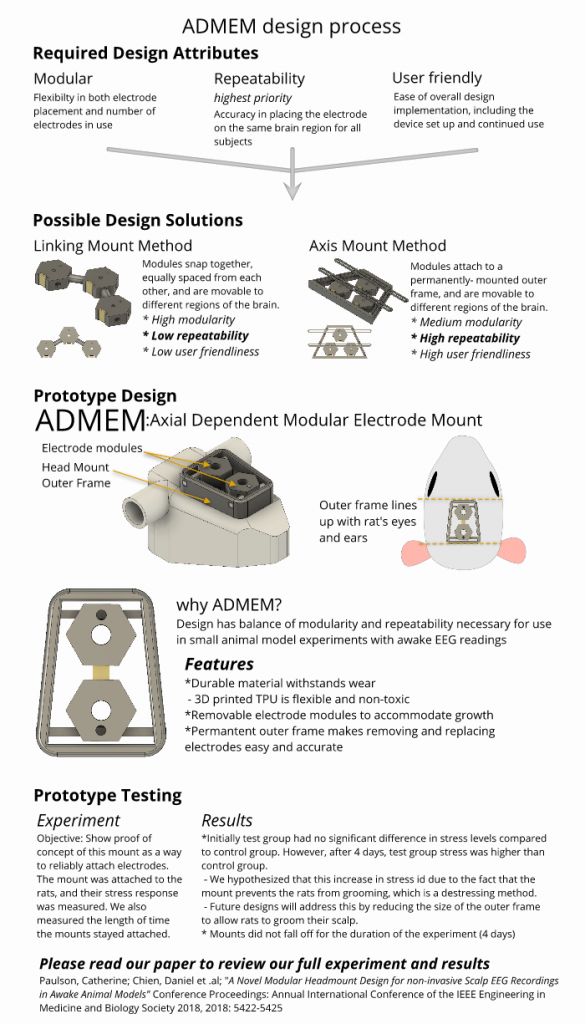

Our team brainstormed the three main criteria we wanted our mount to meet: (1) We wanted a modular design to allow experimenters to control how many electrodes they were using and where to place them. (2) We wanted the design to make it easy to place the electrode over the same region of the brain across different animals in the experiment, so that the data gathered was accurate. (3) We wanted to make attaching the electrodes both user friendly for the experimenters and safe for the animal specimens.

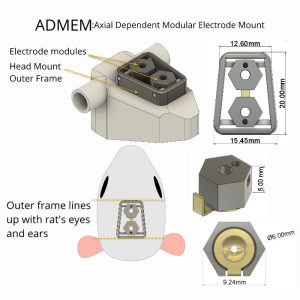

While we brainstormed a few plausible ideas, we settled on the Axial Dependent Modular Electrode Mount (ADMEM) design. This design combined a permanently mounted outer frame with movable electrodes attached to the frame with a crossbar.

Although we’d come up with a design idea, none of the members of our team had much CAD or prototyping experience. I undertook the daunting task of learning CAD software to design our prototype. I used online tutorials to learn Autodesk Fusion 360. In a couple of weeks, I had finished the prototype design for the outer frame and electrode casings. I also did extensive research on 3D printers to understand how to use them to build our prototype. The device overview schematic and the ADMEM design process infographic are entirely my design.

Results

We tested the mount to see (1) how long the mounts would stay attached for and (2) the impact the mounts had on the behavior of the rats. The mounts stayed attached for the duration of the test (four days total). The mounts didn’t affect the rats initially, but after 4 days, there was evidence of anxiety. We hypothesized that the late-induced stress was because the mounts blocked the rats grooming behavior, which is important for de-stressing (imagine how uncomfortable you would be if you weren’t allowed to take off a helmet and wash your hair for a week!). In a future design of our mount, we would allow the electrodes to be removed, allowing the rats to groom themselves. You can read more about the specifics of this experiment in our paper, published in the IEEE EMBC 2018 Conference Journal.

What did I learn from this project?

- I thrive when given the opportunity to learn things. While I’ve always enjoyed learning, most of my education has been structured. I was really excited to learn new skills and explore my creativity. I enjoy challenging myself to be better both for myself and for the group.

- Prototypes don’t have to be perfect, they just have to be good enough to test. This was a big one for me, since I want to add every feature I can think of before testing. But this project showed me the importance of incremental testing. It helps you focus on the crucial aspects of a design and drop the non-essential or useless aspects early.

- Working in groups can be productive and fun. My group mates were amazing to work with. We respected and listened to each other, and took ourselves and our project seriously. We were productive while still having fun, and our product was something we were proud of.